Our foundry technicians and engineering staff are well prepared to provide metallurgical and general casting design support for your design and engineering projects.

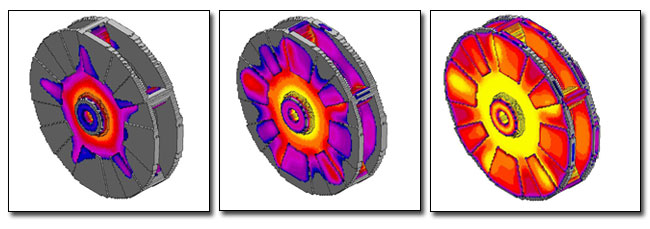

To complement the hands-on expertise and know-how of our foundry personnel, we utilize state-of-the-art solidification software (SOLIDCast) to design foundry gating and rigging to optimize casting integrity.

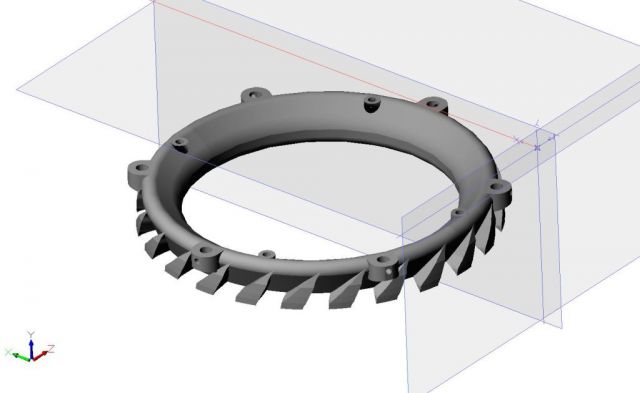

Three-dimensional casting models can be imported from most customer-supplied computer files. If you prefer, our engineering staff can create them.

The merging of this state-of-the-art technology with traditional foundry experience and practices is only one example of our commitment to proactive production strategies.

Rapid prototyping of cores, mold and/or patterns is now available. Rapid prototyping creates a scale model using three-dimensional, computer-aided design (CAD) data. A 3-D printing machine uses the data and builds the model from layers of liquid, powder or sheet material. This process helps turn your idea into a successful product quickly and efficiently.